How does MRP work in SAP?

Índice

- How does MRP work in SAP?

- Is SAP an MRP or ERP system?

- What is MRP run in SAP?

- What are the MRP master data in SAP?

- What is the key to MRP?

- What is the MRP process?

- Does SAP have MRP?

- What is the purpose of MRP?

- How BOM is created in SAP?

- Why is MRP important?

- How to run MRP?

- What does MRP stand for in resource?

- What is the process flow in MRP?

- What are the benefits of material requirements planning?

How does MRP work in SAP?

SAP MRP checks the stock level of the respective material and generates procurement proposals or planned orders which could be either converted to purchase requisitions or production orders based on the MRP settings in material master records.

Is SAP an MRP or ERP system?

Glossary Term: SAP, or Systems Applications and Products, is an ERP system that requires special mention because it is a brand name of a system that is the biggest within the field of offerings.

What is MRP run in SAP?

MRP run or planning run is an engine which is used to fill the demand and supply gap. Issues and Receipts are called MRP Elements. ... Receipts include production orders, purchase requisitions, purchase orders, open production orders, receiving stock transfer order, schedule lines, etc.

What are the MRP master data in SAP?

This role contains functions for maintaining master data in MRP for in-house production. It does not contain any functions that refer to the master data for production types themselves (production with production orders, repetitive manufacturing, Kanban). The maintenance of master data forms the basis of MRP.

What is the key to MRP?

One of the main settings for the MRP planning run within SAP is the Processing Key. This setting is the main indicator for which the MRP planning run will execute.

What is the MRP process?

Material requirements planning (MRP) is a system that helps manufacturers plan, schedule, and manage their inventory during the manufacturing process. It is primarily a software-based system.

Does SAP have MRP?

Material Requirements Planning (MRP), a module in SAP ERP, is a planning tool to help production and procurement planners create feasible and realistic plans so they can quickly initiate the procurement or production processes.

What is the purpose of MRP?

Material requirements planning (MRP) is a system that helps manufacturers plan, schedule, and manage their inventory during the manufacturing process. It is primarily a software-based system.

How BOM is created in SAP?

You create a BOM for the product. In the BOM header, you define a base quantity of the material you want to produce. All other quantities are relative to the base quantity. ... You assign all other materials together with their quantities to the BOM as BOM items or material components.

Why is MRP important?

Why is MRP important? MRP gives businesses visibility into the inventory requirements needed to meet demand, helping your business optimize inventory levels and production schedules.

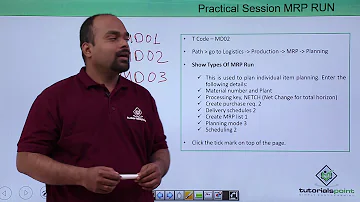

How to run MRP?

- Running MRP for all Products − Use T-code: MD01 or go to Logistics → Production → MRP → Planning → Total Planning → Online. Enter the manufacturing Plant for which you want to take MRP run. Enter Processing key as NETCH. ... − Click the tick mark at the top. − If you are sure on the MRP run, click the tick mark. − The system will take some time to run MRP and calculation is done. ...

What does MRP stand for in resource?

- How is Manufacturing Resource(s) Planning abbreviated? MRP stands for Manufacturing Resource(s) Planning. MRP is defined as Manufacturing Resource(s) Planning very frequently.

What is the process flow in MRP?

- MRP Process flow With MRP, inventory can be optimized via planning receipts according to the needs so that surplus inventory could be avoided. Sales and distribution give concrete customer requirements from the market. In Demand Management, sales are planned in advance via a sales forecast.

What are the benefits of material requirements planning?

- Some of the benefits of material requirements planning (MRP) software include elimination of excess inventory, cost savings, and simplified production planning.